- Power Quality Standards Organization

The organizations responsible for developing power quality standards in the United States include the following: Institute of Electrical and Electronics Engineers (IEEE), American National Standards Institute (ANSI), National Institute of Standards and Technology (NIST), National Fire Protection Association (NFPA), National Electrical Manufacturers Association (NEMA), Electric Power Research Institute (EPRI), and Underwriters Laboratories (UL). While outside the United States, the primary organizations responsible for developing international power quality standards include the following: International Electrotechnical Commission (IEC), Euronorms, and ESKOM for South African standards.

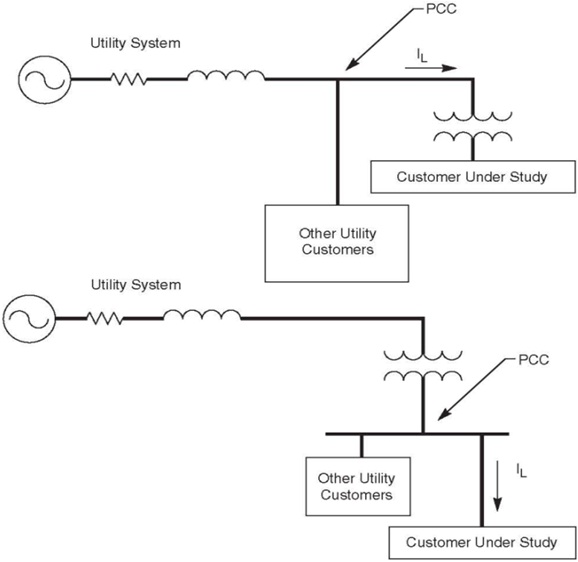

The IEEE was founded in 1963 from two organizations: the American Institute of Electrical Engineers (AIEE) and the Institute of Radio Engineers (IRE). IEEE power quality standards deal primarily with the power quality limits of disturbances at the point of common coupling (the point where the utility connects to its customer or end user).

Five engineering societies and three government agencies founded ANSI in 1918. The ANSI has the official responsibility to adopt standards for the United States. It does not develop standards, but facilitates standards development by qualified groups, like the IEEE.

The genesis of the IEC occurred in 1890 at the Electrical Exposition and Conference held in St. Louis during a meeting of several famous electrical pioneers. IEC power quality standards working groups are concerned mainly about standards that will enhance international trade. IEC’s reference to power quality standards as electromagnetic compatibility standards illustrates that IEC’s primary concern is the compatibility of end-user equipment with the utility’s electrical supply system.

- Other Domestic Standards Organizations

In the United States, other organizations, like EPRI, UL, NEMA, NFPA, and NIST, have also developed power quality standards. Even public utility commissions have adopted power quality standards.

- Other International Standards Organizations

In addition to IEC and ESKOM, the South African utility, The European Standards Community Standards Organization (CENELEC) has developed power quality standards called Euronorms. The International Union of Producers and Distributors of Electrical Energy (UNIPEDE) published a measurement guide for voltage characteristics. The French standards organization, Union Internationale d’Electrothermie (UIE), is preparing a power quality guide on voltage dips, short-duration interruptions, harmonics, and imbalances.

2. Purpose of Power Quality Standards

Power quality standards provide equipment protection from failing or misoperating by setting measurable limits as to how far the voltage, current, or frequency can deviate from normal. By setting these limits, power quality standards help utilities and their customers gain agreement as to what are acceptable and unacceptable levels of service.

3. Types of Power Quality Standards

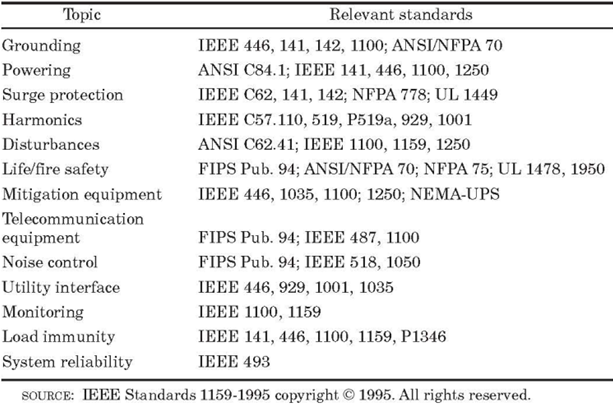

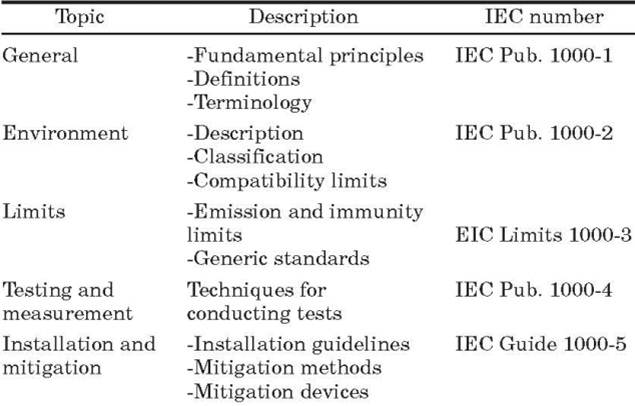

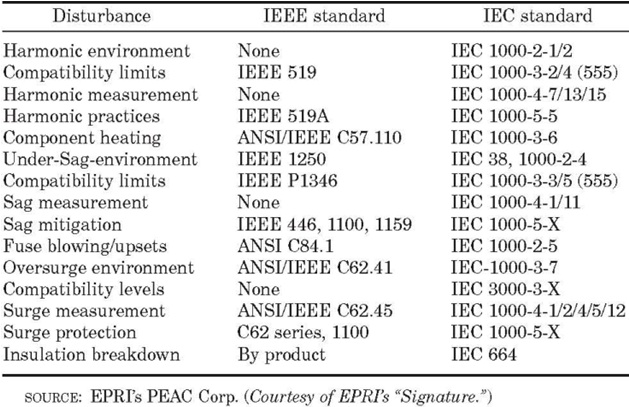

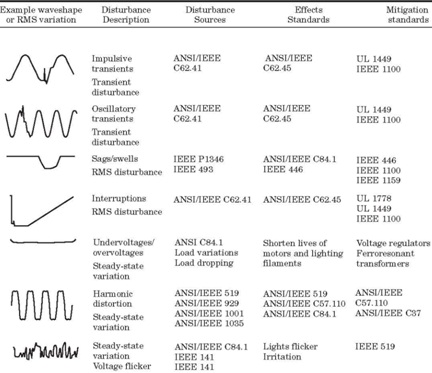

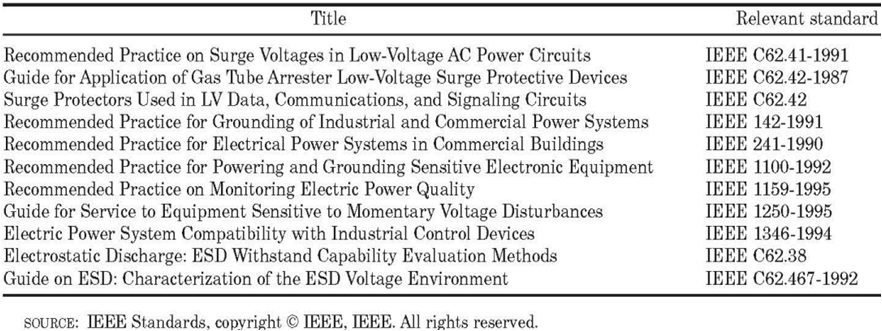

There are so many types of power quality standards that utilities and their customers need to protect their equipment from damage. Table 3.1, from IEEE Standard 1159-1995, provides a summary of the various types of IEEE power quality standards. Table 3.2 provides a simple user guide to IEC standards by organizing them according to general, environment, limits, testing and measurement, and installation and mitigation categories. Table 3.3, which compares the United States and international standards by disturbance and the corresponding purpose of the standard. And Table 3.4 uses this approach to categorize the various United States power quality standards.

- Voltage Sag (Dip) Standards

Voltage sags are typically the most important power quality variation affecting industrial and commercial customers. The IEEE Standard 493-1990, p. 38 already includes voltage sags in the definition of reliability. The most basic index for voltage sag performance is the system average RMS (variation) frequency index voltage (SARFIx).

Standards are needed for the effects of voltage sags on sensitive electronic equipment, called IEEE Standard P1346. This standard contains indices that will allow industrial engineers to evaluate how sensitive their industrial processes will be to voltage sags.

- Transients or surges

ANSI/IEEE C62.41-1991, deals with transients in a building. This standard is concerned with the effect of transients on the load side of the meter. It categorizes the location of the transients and types of transient waveforms. The three locations are category A, anything on the load side of a wall socket outlet; category B, distribution system of the building; and category C, outside the building or on the supply side of the main distribution boards for the building.

- Transient Voltage Surge Suppressor (TVSS) Standards

The most popular way to protect your computer and other sensitive electronic equipment is to use a transient voltage surge suppressor or TVSS. This device guards the voltage against a voltage transient or surge and keeps it from damaging your equipment. The primary standard for the TVSS is Underwriters Laboratories Standard UL1449.

- Uninterruptible Power Supply (UPS) Standards

The purpose of an uninterruptible power supply system is to protect sensitive equipment from voltage surges and loss of power. A UPS often contains both a surge suppression device and some type of power supply, like a battery or a motor-generator set. For safety reasons, Underwriters Laboratories has developed a standard specifically for UPSs, UL 1778.

- Voltage unbalance

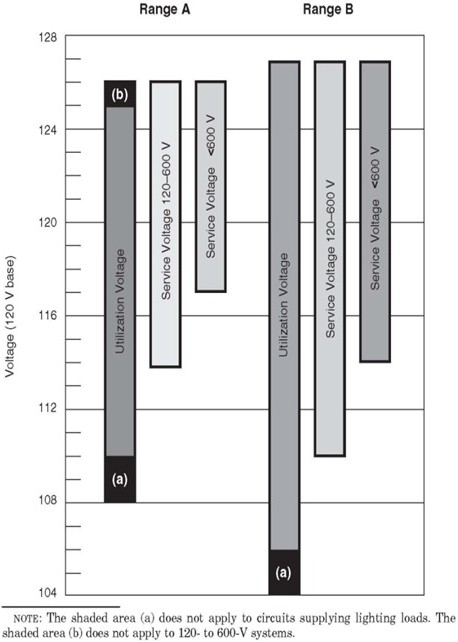

The primary standard for voltage unbalances as well as steady-state voltage requirements is ANSI C84.1-1995. It specifies that equipment is designed to operate at voltages not to exceed +6% or less than -13% of the nominal 120/240 system voltage. Figure 3.1 summarizes these voltage standards. Range A applies to normal conditions. Range B applies to short-duration or unusual conditions.

- Voltage Fluctuation or Flicker Standards

The primary United States standards for voltage fluctuation are contained in IEEE 519-1992, and IEEE 141-1995. The international standard for measuring flicker is IEC 1000-4-15, and for setting flicker limits for individual appliances is IEC 1000-3-3. All these standards attempt to limit the lighting flicker so that it does not irritate a person seeing it.

- Harmonic Standards

Electronic equipment cannot stand more than 5% harmonic voltage distortion factor, with a single harmonic being no more than 3% of the fundamental voltage. The harmonic standard for the United States, IEEE 519-1992, recognizes that the primary source of harmonic currents is nonlinear loads located on the end-user (utility customer) side of the meter. IEEE 519-1992 sets current limits at the point of common coupling (PCC), as shown in Figure 3.2.

- Transformer Overheating Standards

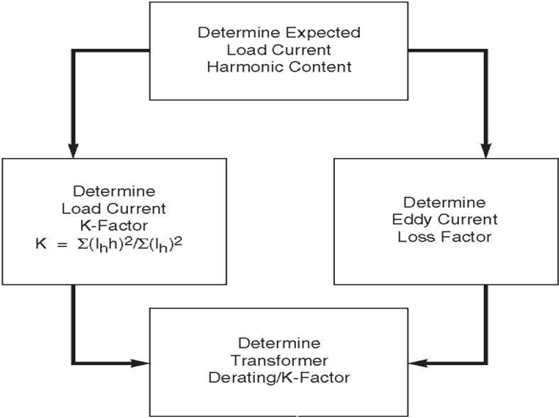

ANSI/IEEE Standard C57 series addresses the problem of harmonics causing transformers to overheat. IEEE and UL have adopted standards to either derate regular transformers or to design special transformers that can withstand the effect of harmonics. These specially designed transformers are called K-factor transformers.

- K factor

A K-factor transformer has certain features that allow it to handle the extra heating of harmonic currents. Underwriters Laboratories, in UL 1561, developed the K-factor constant to take into account the effect of harmonics on transformer loading and losses. The steps in calculating the K factor of a transformer are shown in the flowchart in Figure 3.3. In summary, the purpose of the K-factor rating is to rank transformers for harmonics, reduce skin-effect losses, and reduce the possibility of core saturation.

- Neutral Conductor Loading Standards

Single-phase nonlinear electronic loads will draw current only during the peak of the voltage waveform. These loads combined in a three phase circuit produce triplen harmonics (multiples of third-order harmonics, like third, ninth, fifteenth). Triplen harmonics do not cancel one another but are additive and return exclusively through the neutral conductor. Thus, the neutral current may exceed the capacity of the neutral conductor. The international community in IEC 1000 3-2, has set limits for triplen harmonics generated by various classes of single-phase equipment.

- Static Electricity

Static electricity can often be the hidden cause of poor power quality. The National Institute of Standards and Technology recognized this concern when it published the Federal Information Processing Standards Publication (FIPS Pub.) 94, in 1983. Figure 3.4 from FIPS Pub. 94 shows a static discharge from a finger to a switch. FIPS Pub. 94 mentions that by keeping the humidity at least 50 percent, increasing the conductivity of carpeting, furniture, and upholstery, and treating shoes and clothing with antistatic preparations, users can reduce static discharges considerably.

- Telephone Power Quality Standards

Just as computers are sensitive to variations in power quality in other applications, they are sensitive to the same variations in their applications to telephones. Table 3.5 lists some of those standards that are critical to protecting the smooth operation of telephone equipment. In addition to these telephone standards, utilities have IEEE Standard 487, Recommended Practice for the Protection of Wire Line Communications Facilities Serving Electric Power Stations.

- Grounding and Wiring Standards

The primary standards for wiring and grounding are IEEE Standard 446, IEEE Standard 141-1993, IEEE Standard 142-1991, IEEE Standard 1100, FIPS Pub. 94, and the NEC, ANSI/NFPA 70. While the NEC is concerned with providing adequate grounding that protects the public from electrical shock, these other standards are concerned with setting grounding standards that protect sensitive equipment from damage or misoperation caused by the extraneous ground current.

- Sensitive Electronic Equipment Standards

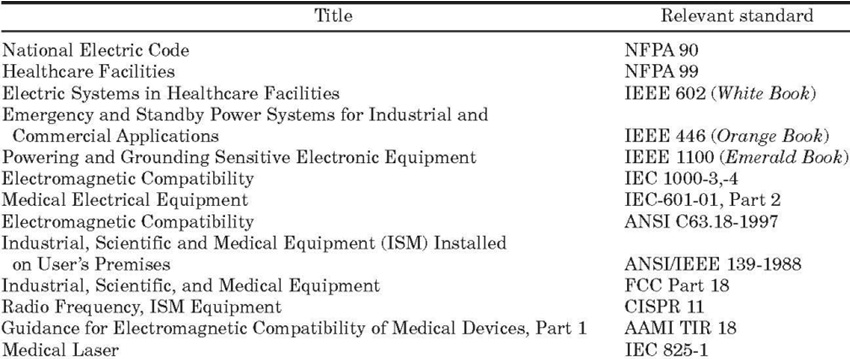

The health care industry’s increased use of sensitive electronic equipment to monitor, diagnose, and sustain the vital functions of its patients has caused the IEEE, NFPA, and IEC to develop standards. Some of these health care power quality standards are listed in Table 3.6. Other industries, such as the pulp and paper industry, relied on general power quality standards for electrical systems, such as IEEE-519-1992.

- Trends in Power Quality Standards

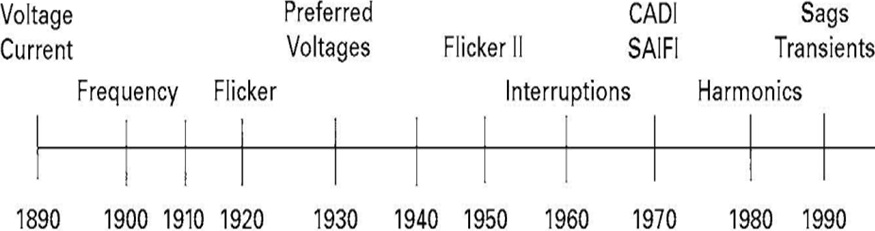

Over the years, various standards organizations have developed power quality standards whenever a particular power quality problem appeared. One of the outcomes of utility deregulation will be the need to determine who is responsible for a particular power quality problem and what is expected of them to mitigate that problem. Figure 3.5 illustrates this historical trend.

- Written by: admin

- Posted on: 04/07/2021

- Tags: ANSI, Electric Power, IEC, IEEE, NEMA, Quality Standards